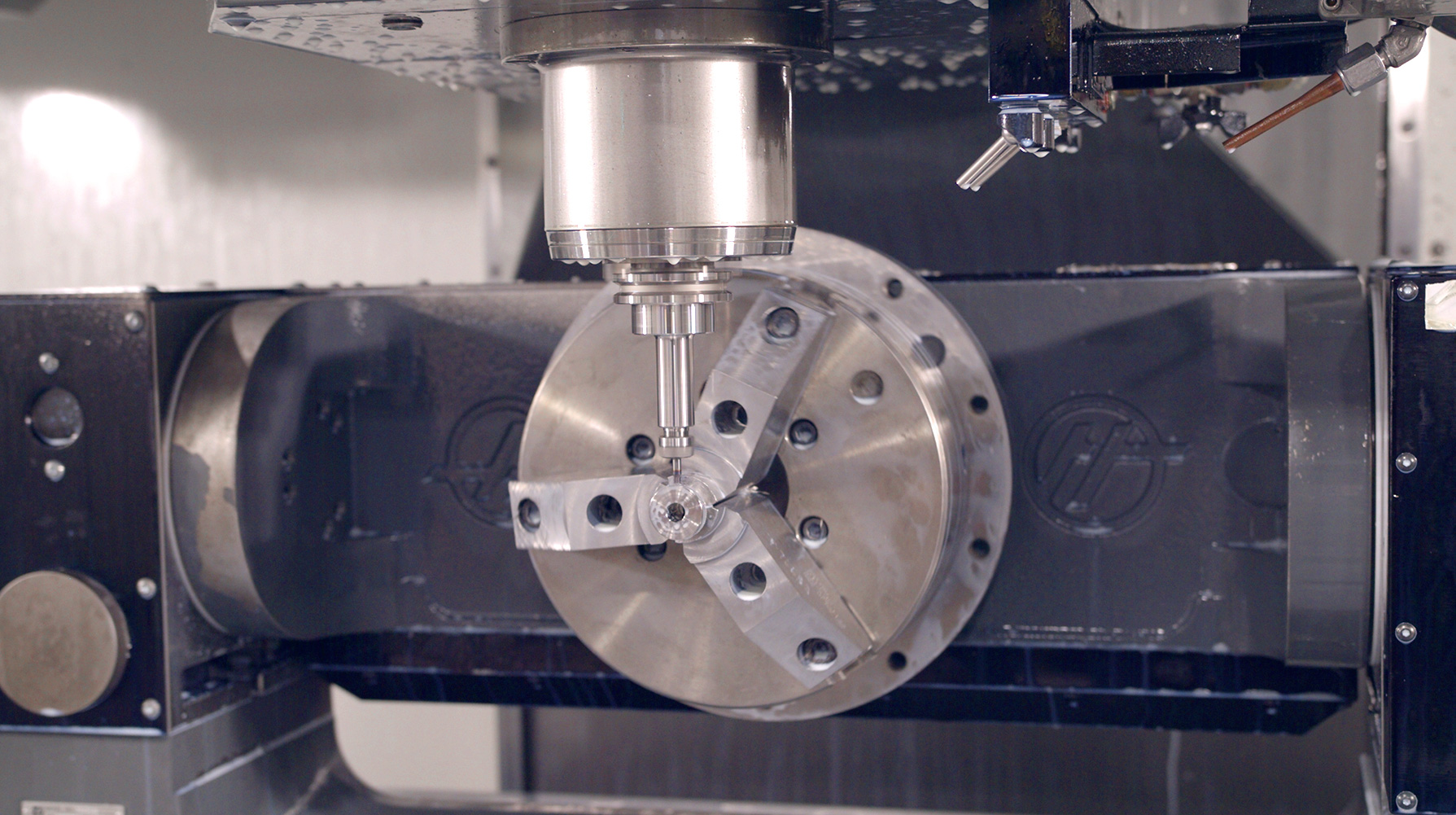

CNC Milling

Ace Precision’s CNC milling machines have vertical and horizontal capabilities, facilitating the development and production of a wide variety of complex precision-machined parts. With two pallet shuttle systems, parts can be machined on one pallet while loading parts on the other pallet, thus reducing production time. The pallet changing system also provides the option of multi-operation workholding, resulting in lower setup times, which allows combining of operations to reduce handling and improve machine uptime. In addition, our machines are outfitted with 4- and 5-axis rotary indexing tables and dedicated fixtures on palletized tombstones, resulting in significant reduction in variation in production runs, improved quality and reduced costs. And recent equipment investments have added controls with faster code processing power to run larger high-speed dynamic machining programs for superior profile control and surface finish. Our in-house CNC milling equipment can handle parts up to 64″ x 32″ x 30″.