Engineered Coatings

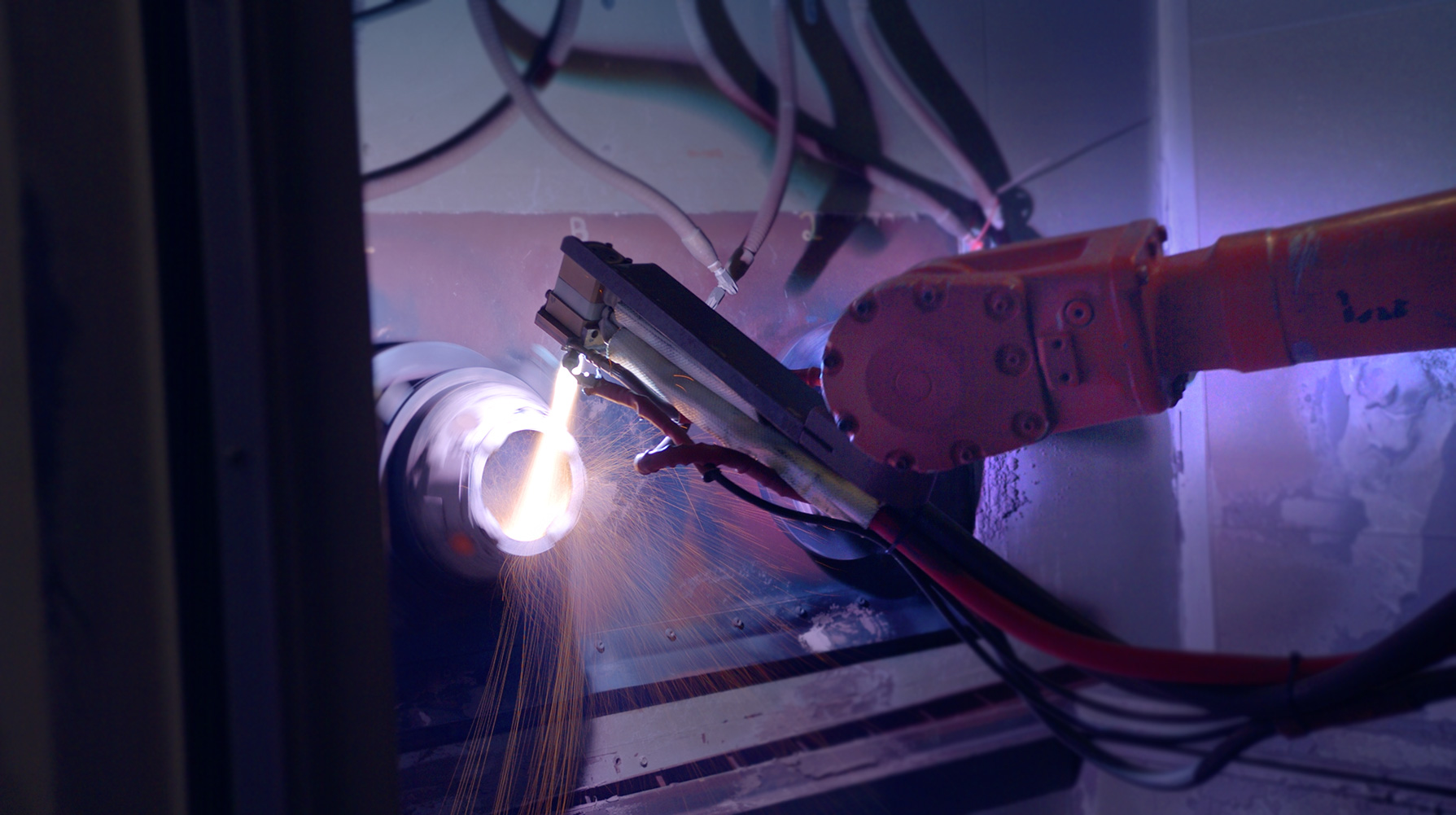

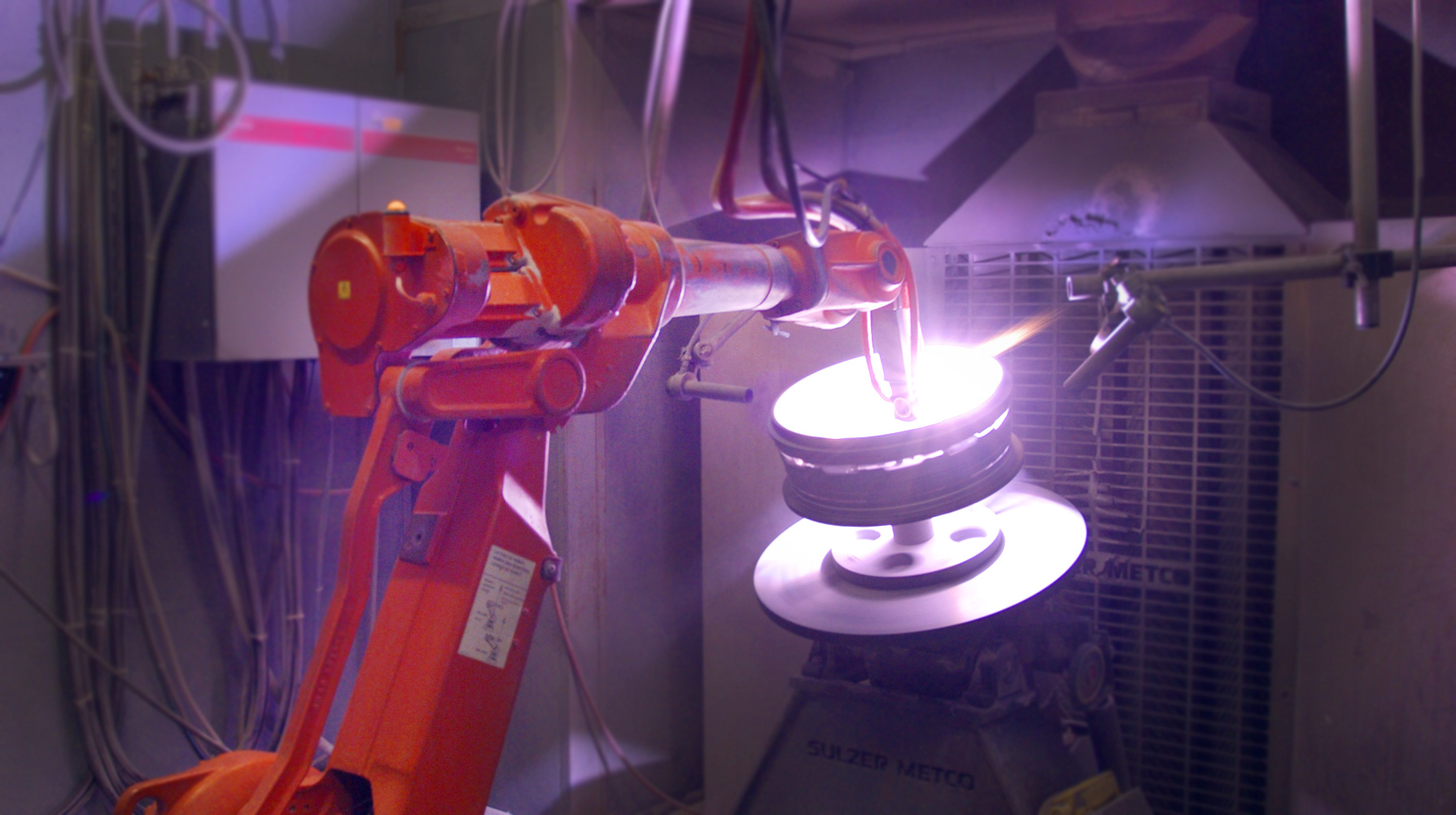

Ace Precision is a proven leader in the thermal spray coatings industry, utilizing state-of-the-art robotic technology to consistently and accurately meet a wide variety of industry and customer standards. Our 3D modeling software, computerized controllers, 6-axis robots, and auxiliary axis coordinated motion turntables meticulously control the process inputs/outputs.