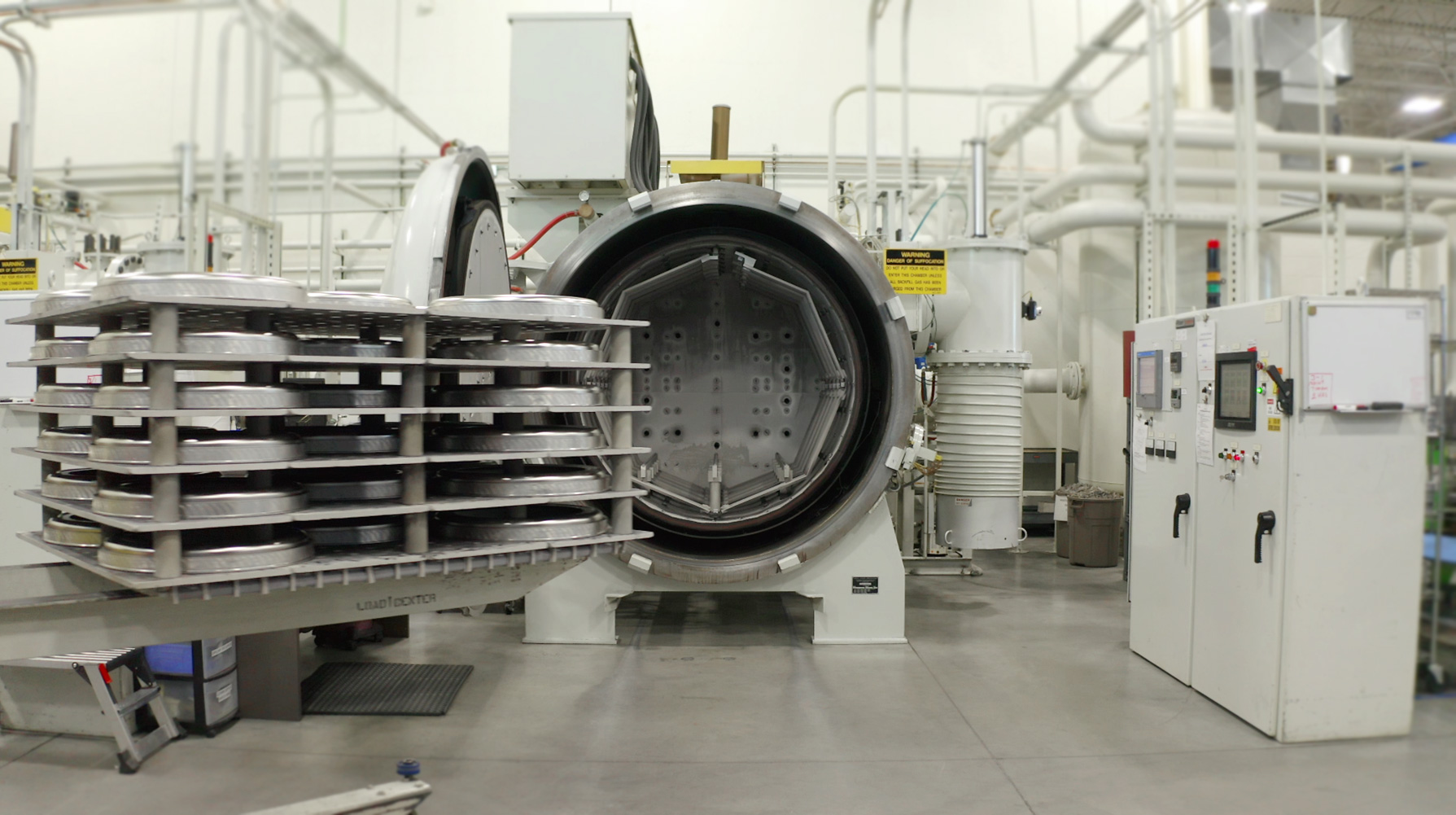

Thermal Processing

Ace Precision is an industry-leading provider of high-quality, state-of-the-art thermal processing technologies.

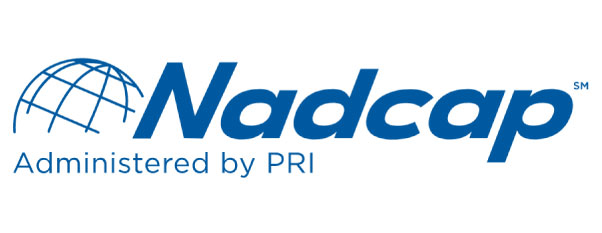

Heat Treat Nadcap

Certificate Number: 3095210525

Expiration Date: 30 November 2024

Accreditation Length: 36 Months

Expiration Date: 30 November 2024

Accreditation Length: 36 Months

Heat Treat Nadcap

Certificate Number: 5111210526

Expiration Date: 30 November 2024

Accreditation Length: 36 Months

Expiration Date: 30 November 2024

Accreditation Length: 36 Months