Quality System

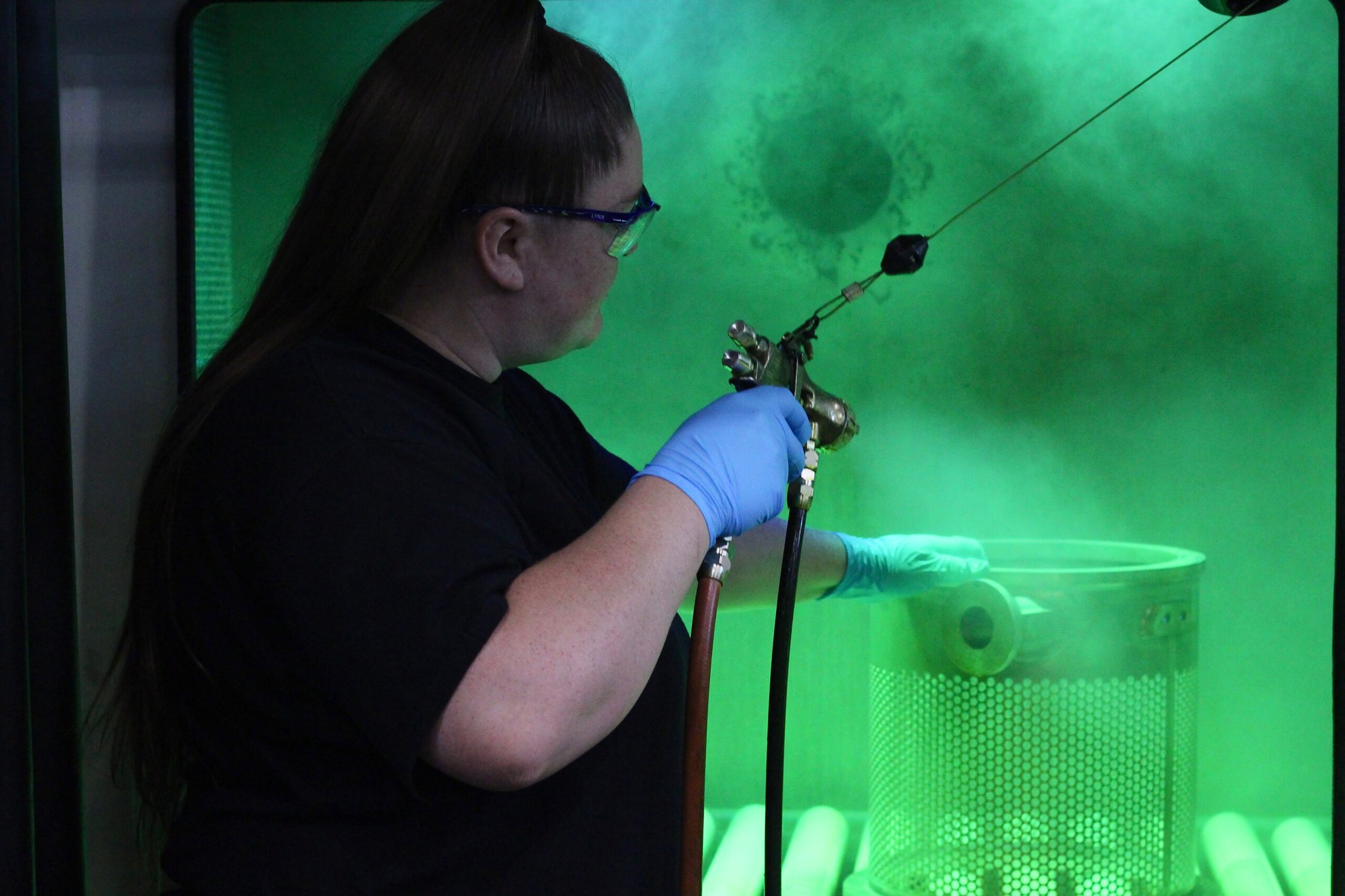

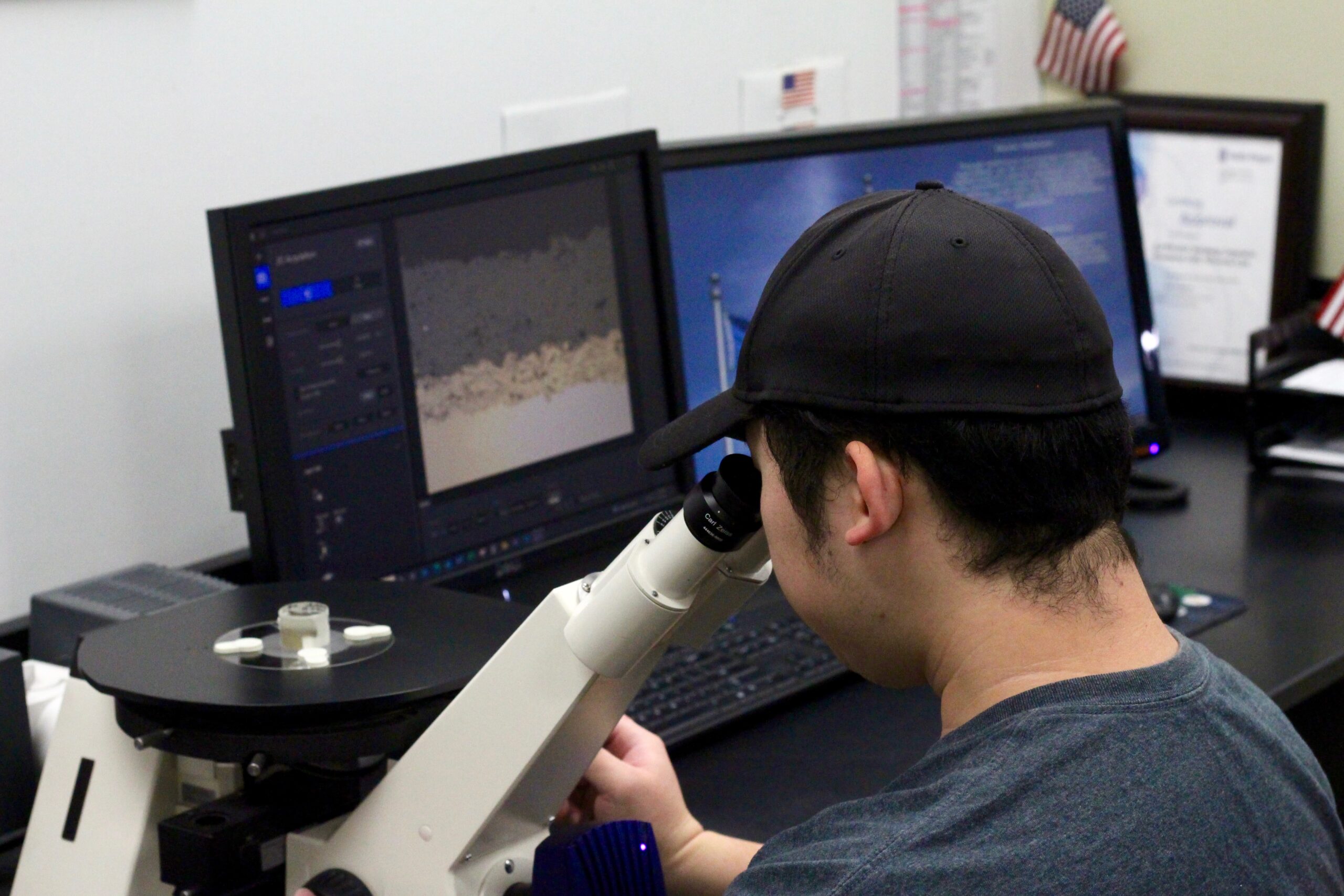

Ace Precision services several industries, including aerospace, which requires compliance to quality management system requirements beyond ISO 9001. We have built and continue to maintain a highly integrated quality system not only capable of capturing industry, Nadcap, and customer-specific requirements, but also effectively identifying, managing and driving internal process improvement initiatives.

AS9100 PRI

Certificate Number: 16931

Expiration Date: 18 December 2025

Accreditation Length: 36 Months

Expiration Date: 18 December 2025

Accreditation Length: 36 Months

NDT Nadcap

Certificate Number: 3095198678

Expiration Date: 31 August 2023

Accreditation Length: 24 Months

Expiration Date: 31 August 2023

Accreditation Length: 24 Months

NDT Nadcap

Certificate Number: 5111198677

Expiration Date: 31 August 2023

Accreditation Length: 24 Months

Expiration Date: 31 August 2023

Accreditation Length: 24 Months