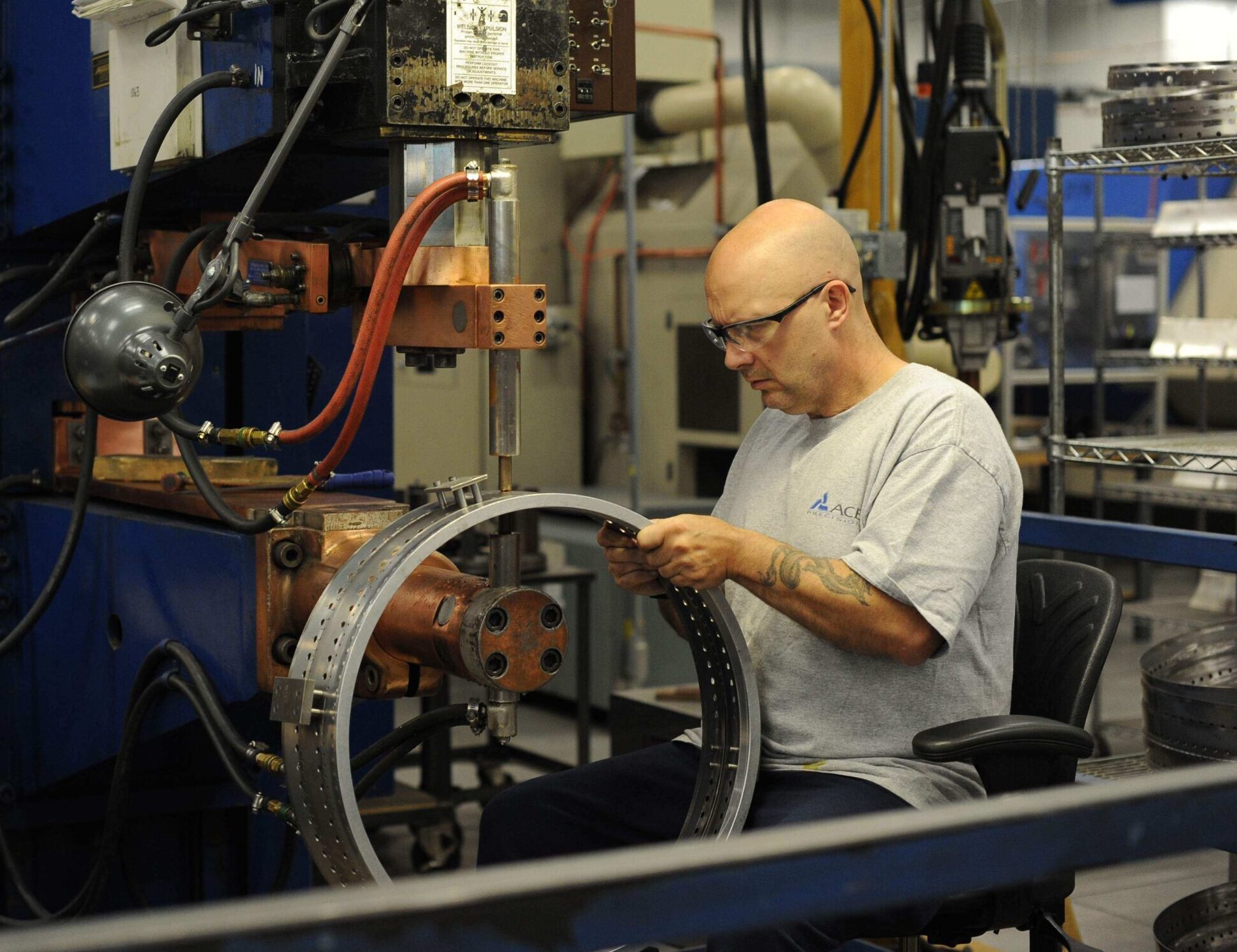

Metal Joining

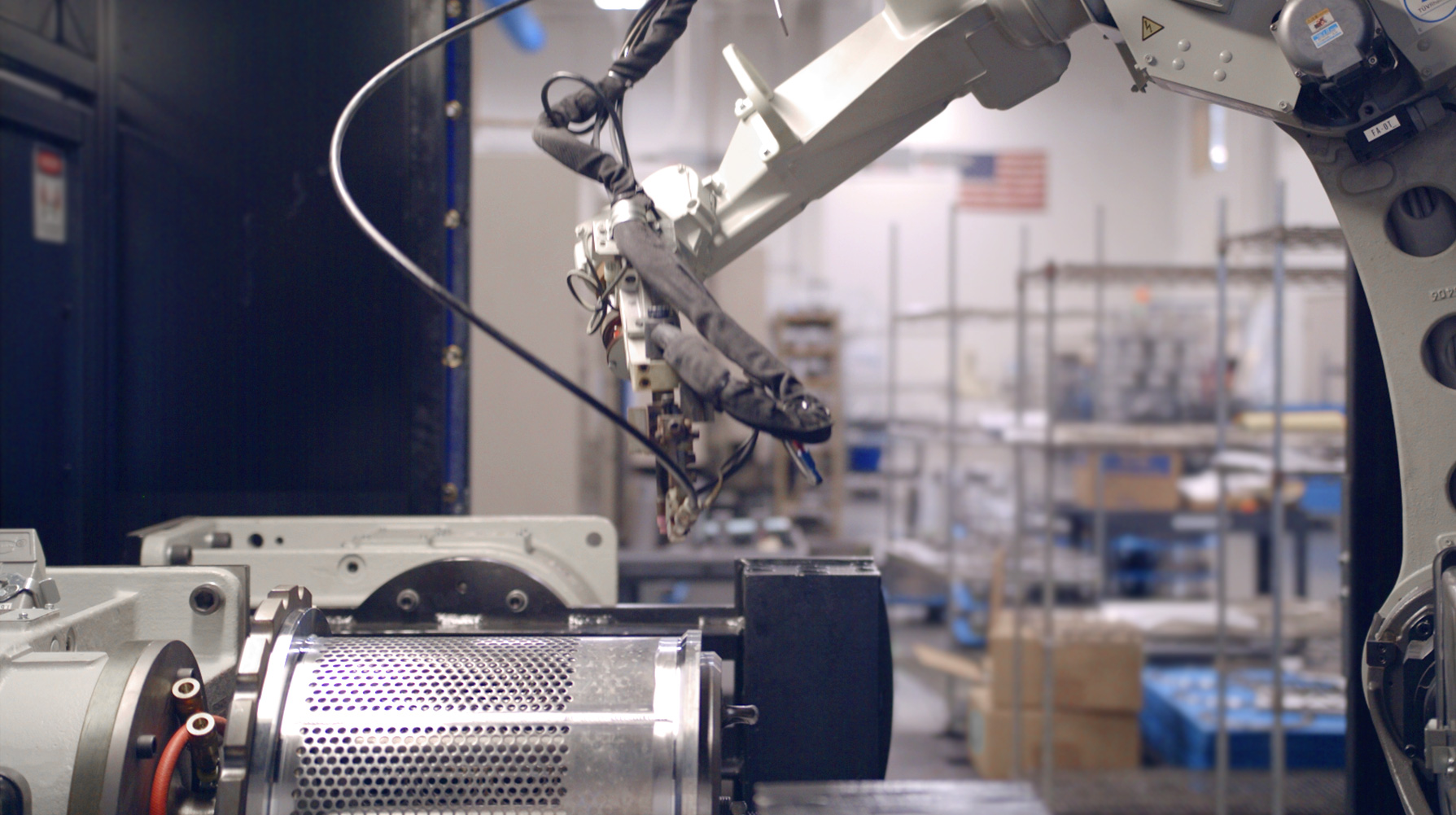

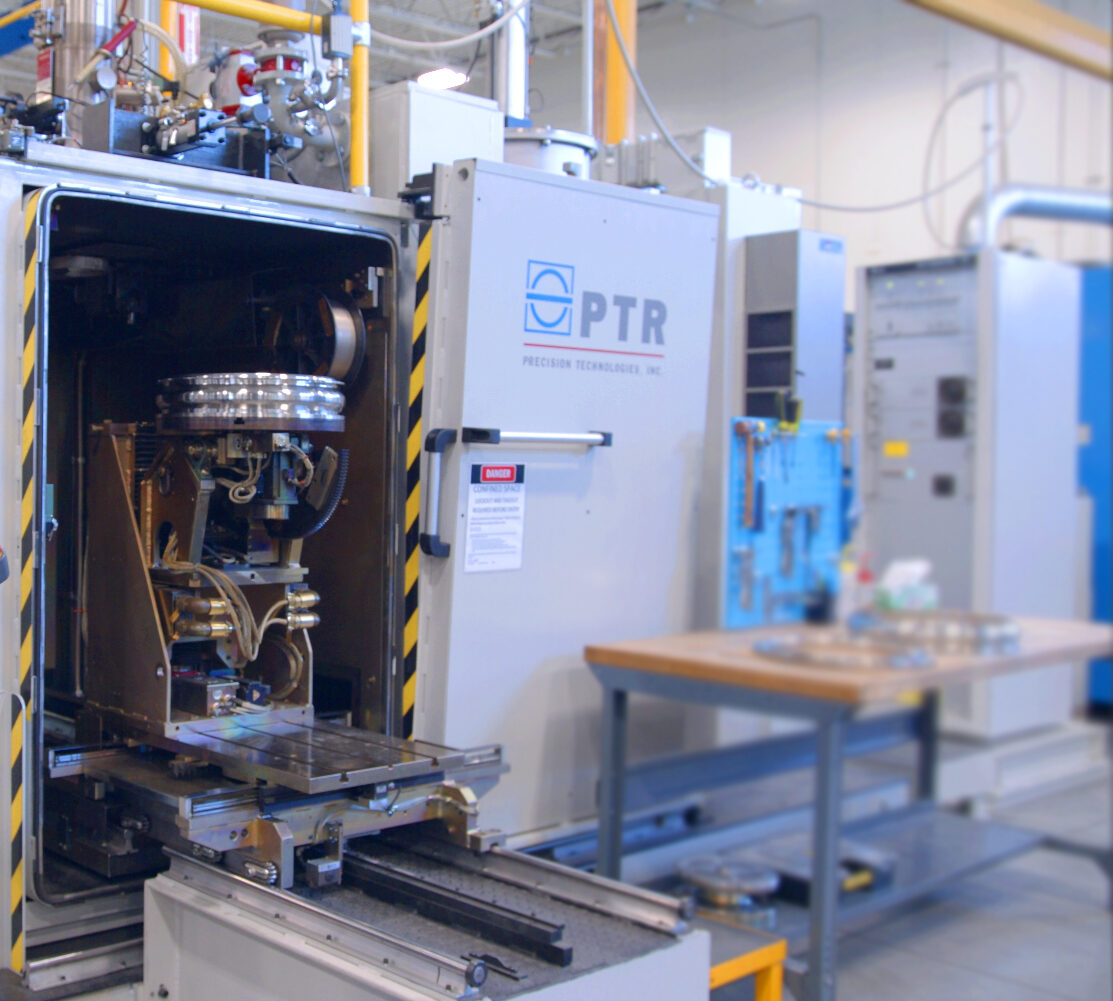

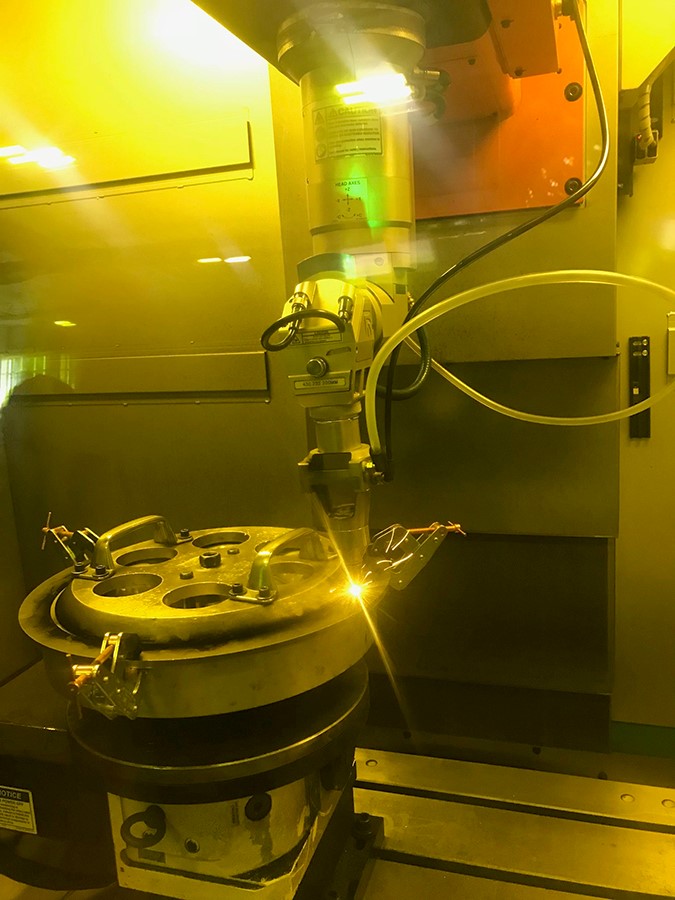

Welding specialty metals is a core competency of Ace Precision. As a well-respected aerospace-accredited supplier, Ace Precision has a reputation for precision welding of the highest quality and safety standards. The projects we take on are complex, requiring a high level of welding expertise beyond the capability of most welders and welding operations. Our processes are highly engineered and tightly controlled with rigid standards of acceptance and welder qualifications.